Place of origin:China

Brand name:OEM

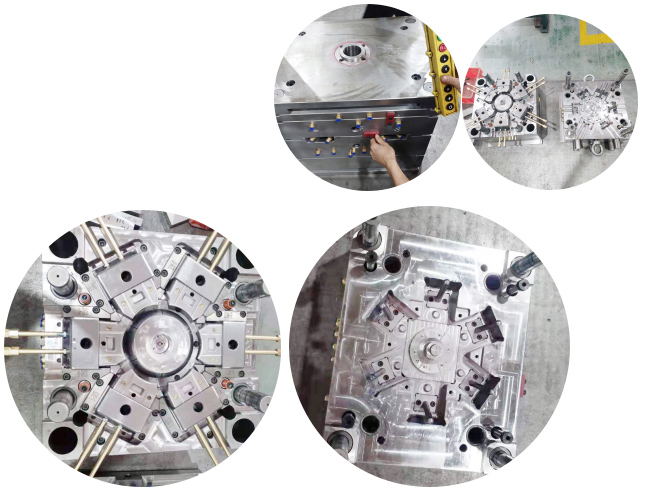

Shaping mode:Plastic injection mold

Product material:Plastic

Mold:Injection

Size:According to your drawings

Service:OEM

Color:Various colors

Packaging details:PEbag with carton

Port:Shenzhen

Brand:

Customization

Main Business :

♦ Plastic Injection Molds for Export

♦ Plastic Injection Molding Production

♦ CNC Milling Machining Service

♦ Assembly and Packing Service

| Mould base | LKM,HASCO,DME or upon customer's requirement |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Cavity | SINGLE/multi 1*1 1*2 etc |

| Mode Gate | Fan gate,sub gate,pin point gate,valve |

| Ejection system | Stripper plate,lifter,push bar |

| Runner | Hot/cold type |

| Plastic material | HDPE,PP,NYLON,PEEK,LDPE,ABS |

| Mould life | 300,000-1.000,000 shots |

| Lead time | 15-35days after deposit received |

| Specification | Follow |

PTS MOULD with ISO 9001 Certifited , senior technicians,having own Reserch and Develop Team,Sales Team,Production Team and QC Team.

Ulite specialize in custom fabrication service as per customer design drawings with processing methods:

Custom plastic Injection Mold and Injection Molding Service,CNC Machining Milling Service and Rapid Prototyping Service.We accept Low Volume Production and Mass Production both.

Our product quality and service are highly recognized by customers all over the world,it is honored to have customers around the world from America,England,Germany,Switzerland ,Australia and etc.

Next:

Die Casting Mold