we have more than 13 years experice on mold, and have a professional team. we will give you the proper advise about your product development. we can do the mold, whatever you supply the sample or drawing or picture.

Mold Base:LKM,HASCO

Runner:HOt Runner,Cold Runner

Mold Weight:50K-10000Ton

Injection Machine:80-2500Ton

Process Machings:CNC,Cutting,EMD,Drilling,Thread,Carved

Brand:

CustomizationPayment:

L/C,T/T,Western Union payments for offline orproduct origin:

GuangDong,ChinaColor:

Customized colorsshipping port:

Shenzhen,GuanzhouLead Time:

30daysMaterial:

AluminiumSurface Quality:

Painting,Sand blasting,OiledCertification:

ISO9001:2015Application:

Optional

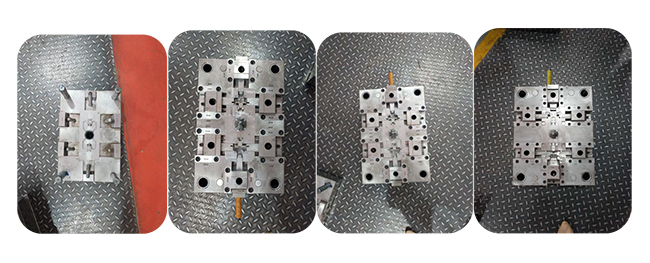

Die casting mold

| Place of | Guandong,China(Mainland) |

| Brand Name | OEM |

| Model Number | ODM |

| Shaping Mode | Die Casting |

| Product Material | Aluminium |

| Serivce | customized/Design |

| Drawing Formation | 2D and 3D igs or stp format |

| Tolerance | +/-0.02mm |

| Dimensions | Customized Sizes |

| Mold Life Time | 50,000 shots |

| Sample Lead Time | 20-35 days |

|

Packaging Details Port |

1,With plastic bag,with pearl-cotton package |

| 2,To be packed in cartons | |

| 3,Use glues tape to seal cartons | |

| 4,Deliver out by DHL,UPS | |

| Or According to customer'requirement | |

| Shenzhen,Guangzhou |

Die casting, stamping, plastic mold, injection molding manufacturers, in the domestic business field is in a leading position, through the ISO9001 quality system, into the advanced technology and high-quality staff!

Related Tags :