Brand:

CustomizationPayment:

T/T,Western Union,MoneyGram payments for offlproduct origin:

Guandong,ChinaColor:

Blackshipping port:

ShenzhenLead Time:

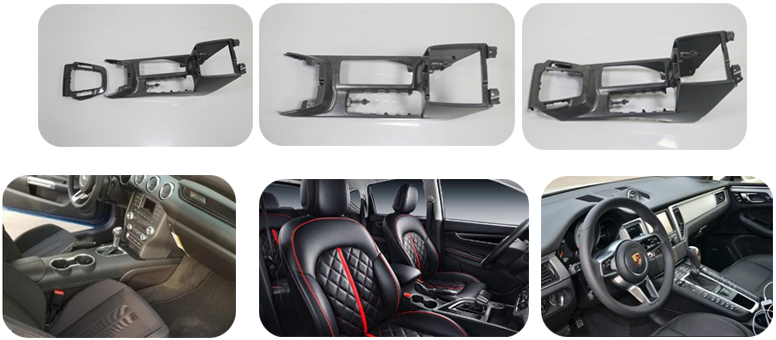

30daysAutomobile Plastic Injection Molding

| Place of Origin | Dongguan,China(mainland) |

| Shaping Mode | Plastic injectio |

| Product Material | Plastic |

| Product | Auto body |

| Mold steel | S136,H13,718H,NAK80 etc. |

| Mold base | HASCO,DME,LKM |

| Cavity | 1*1 |

| Mold life | 500,000-1,000,000shoots |

| Mold Runner | Cold Runner,Hot Runner |

| Surface Treatment | Texture,Polish,EDM |

| Processing Trade Form | OEM & ODM |

| Main Product | Auto parts,Commodity,Electric parts |

Supply Ability:60 Set/Sets per Month Automotive Moulding Manufacturer

Packaging details:Wooden case or as customer's request

Port:Shenzhen or Guanzhou

What we need for quotation?

If any inquiry about plastic moulds,kindly pls send us details as below:Related Tags :

Previous:

Mold of Automotive Control