Place of origin:Guangdong,China

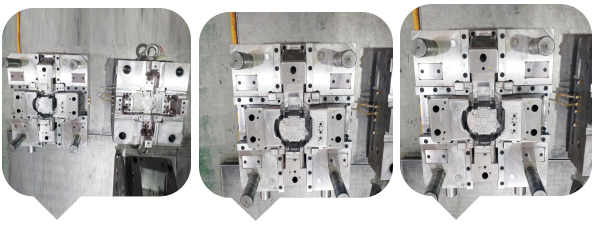

Shaping Mode:Plastic mold

Mould life:500000H

Gate type:Sub-gate

Accept drawings:IGS,STP,PDF,CAD

Method:Injection mold

Business type:Manufacture

Packaging detail:Carton or as required

Surface treatment:Heat treatment

Processing way:Plastic mold

Brand:

CustomizationColor:

BlackLead Time:

30 days

| Avantages | High quality in made |

| Passion,responsibility | |

| Delivery in time | |

| Material | ABS,POM,PP,PU,PC,PA66,PMMA,PVC,PVE |

| Aluminum,Brass,Steel,Stainless | |

| The services we can provide for CNC mode and rapid prototyping | 1.Industry design |

| 2.Small quality parts parts&aluminum parts machine | |

| 3.Reverse engineering | |

| 4.Injection molding | |

| 5.Rapi | |

| Practicable file formats | IGS,STP,CAD,PRO-E |

PTSMOLD on-stop service for plastic product customizing works.We provide mold design,precision plastic mold making,custom best quality plastic injection molding,Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

Related Tags :