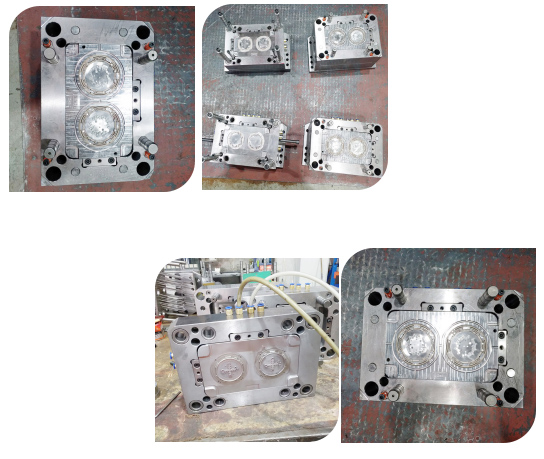

Shaping Mode:liquid injection mold

Product Material:steel

Prpduct:electronic product

Mold material:50cc,45#,P20,s136 etc.

Mold base:LKM,HASCO or Customized

Mould life:according to your requirement

Tooling machine:high speed roedels CNC/EDM/engraving/Wire-cutting

Brand:

Customizationproduct origin:

ChinaColor:

Double colorshipping port:

ShenzhenLead Time:

30days

Double color injection mold

Our company was founded in 2013, mainly engaged in the development and manufacture of precision injection mold.the plastic industry co., LTD mainly engaged in overseas business was established.Look forward to building a good relationship with you.!

| Steel Tolerance | 0.02mm-0.05mm |

| Biggest part Weight | 500G/13Pound |

| Surface Finish | Texture/sandy/MT/YS/SPI/Glossy |

| Runner | Hot Runner/Cold Runner |

| Package type |

Products Packaging MethCods: 1-Wrapped with plastic bag or pearl-cotton protective packing material. 2-Put 5 layers standard export cartons with rigid protective layer. 3-Use glue tape to seal cartons. 4-Loading on pallet with protective rigid corners 5-Loading container for sea shipping. Remark:if need DHL,FEDEX or UPS and so on express then no pallet needed |

| Design softwar | UG,ProE,Auto CAD,Solidworks,etc. |

| Gate Type | Edge gate,sub-gate,pin gate,side gate,etc. |

FAQ:

Q: Which kind of product can you do?

A: Plastic injection molding and mass production for plastic parts.

Q: Which kind information need for quotation?

A: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample or tell me your idea,we will help to finish the 3D drawing design.

Q: How long will be the injection mold finished?

A: Usually it will take about one month to finish the mold

Q: How about the samples?

A: After mold finished. We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.

Q: How about the mould modify?

A: You can tell us your comment about the samples after you receive them.If there is any dimension different from the drawing,we will modify the mold for free in our side and ther make the new samples

Q: How about the proprietary rights of the plastic injection mold?

A: Customer paid the mould so it all belong to Customer.

Related Tags :