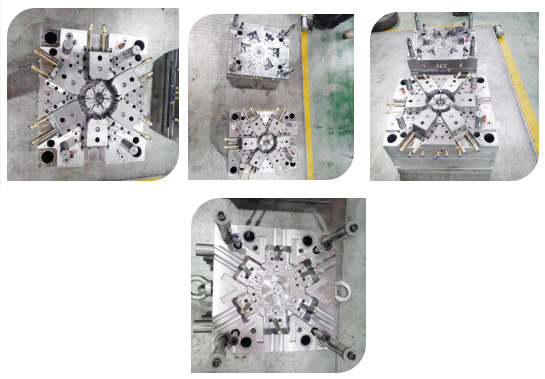

Shaping Mode:Plastic Injection Mold

Product Material:Steel

Mould base:P20/718/2316/2738

Mold base:HASCO etc.

Cavity:Sing or Multi

Brand:

CustomizationPayment:

Automobile parts mouldproduct origin:

ChinaColor:

Blackshipping port:

ShenzhenCertification:

ISO9001:2015Application:

Automobile parts mould

| Place of origin | China |

| Design software | UG,PROE, CATIA, SOLIDWORK ,CAD |

| Surface treatment | Polish,Etched,Texture |

| Service | Customized OEM |

| Runner | Hot Runner\Cold Runner |

| Delivery Time | 35 days |

| Packaging Details | Standard exported wooden box packed |

| Mold Life | 500,000-1,000,000 shots |

Related Tags :